“It’s stone, but not as we know it!”

More than twice as strong as natural basalt, Volkanite® cast basalt has been used successfully in heavy industrial applications for over 60 years. Basalt casting was originally developed in the Czech Republic to be used as a replacement to iron and steel which was in short supply after WWII – the crushed natural basalt is heated back to molten lava and then poured into moulds to make components such as pipes and floor tiles, which are incredibly hard wearing and abrasion resistant >> See Videos Below

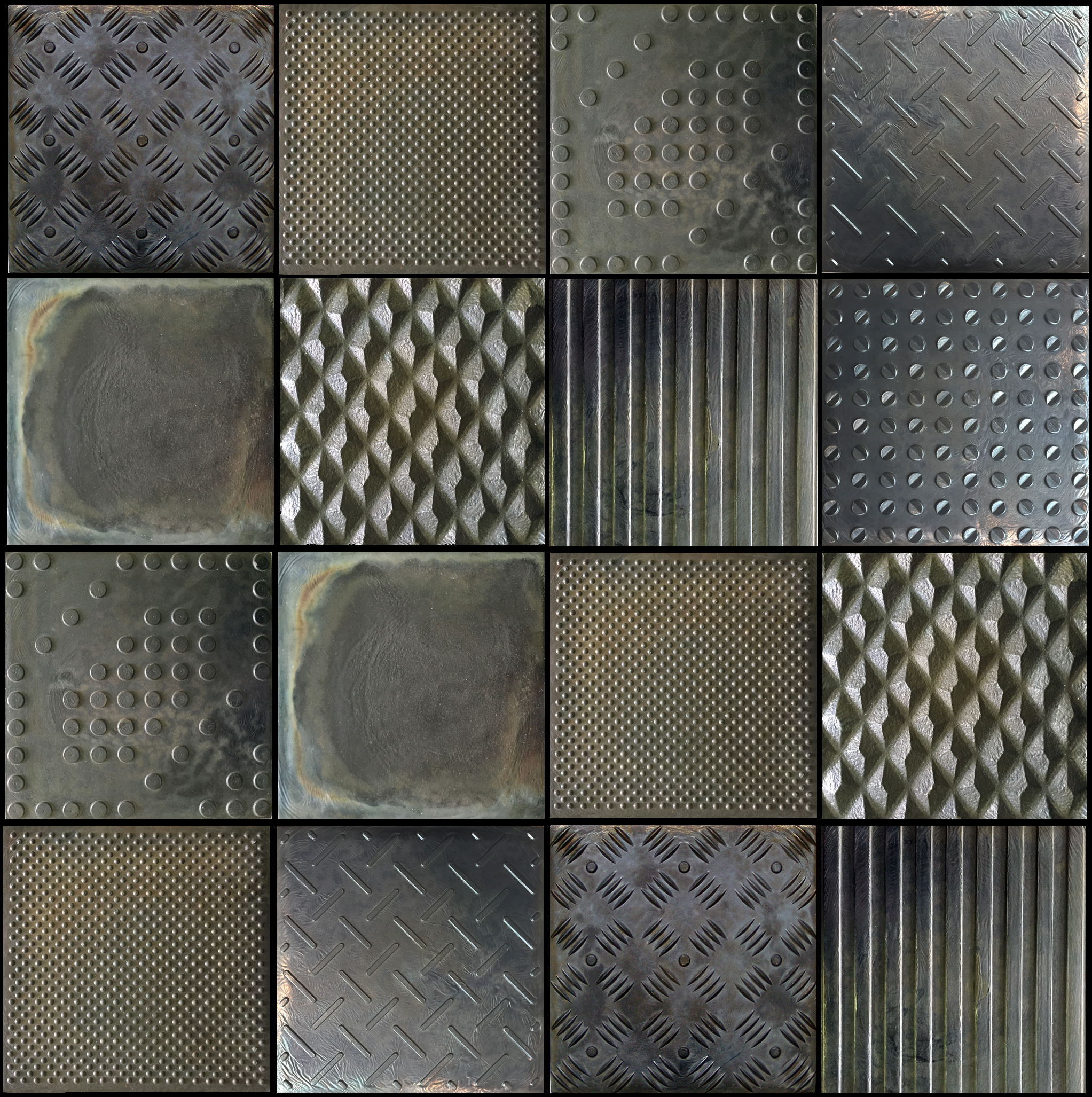

Cast basalt can be formed into a diverse range of shapes and surface patterns – including bespoke designs (min 325m2). During the cooling process the surface of the material achieves a glass-like patina, with an iridescence and texture that is unique to each piece.

Volkanite® cast basalt is now being introduced for the first time in a special format for a wide range of architectural applications including external paving; floor tiles; cladding and special surfaces. With unrivalled abrasion resistance, chemical resistance and flexural strength, Volkanite® delivers dramatic and aesthetically unique paving solutions for public open spaces, pavements, courtyards and many other situations.

To minimise transportation distances, Volkanite® is produced in the Czech Republic utilising high grade raw basalt material that is quarried within 20 miles of the factory. Environmental and health impact are strictly managed and controlled; raw materials are recycled and never wasted.

Various industrial designs available, from patterned anti-slip to plain finish; square, rectangular and hexagonal shapes.

The cooling process…

Volkanite for a range of industrial and architectural applications…

The casting process…